We integrate the digital technologies of Industry 4.0 not only into mechanical processes but also with data-driven decision-making systems, creating flexible and intelligent production processes supported by real-time analytics.

These solutions not only enhance operational efficiency but also provide businesses with a competitive edge and enable a sustainable digital transformation.

01

IoT sensors enable seamless data sharing between machines on production lines. Real-Time Data Analysis Systems identify bottlenecks and improve efficiency in energy and workforce utilization.

02

| AI-Powered Decision Support Systems analyze large datasets to identify the root causes of process issues, enabling faster and more accurate decision-making. |

03

| Cyber-Physical Systems (CPS) facilitate digital simulations of physical processes. Digital Twin Technology creates digital replicas of machines, preventing failures and ensuring uninterrupted production. |

04

Robotic Process Automation (RPA) increases the flexibility of production lines. Flexible Manufacturing Systems (FMS) optimize robotic processes, reduce labor costs, and enhance production adaptability.

05

| Cloud Computing Solutions ensure the secure and accessible management of large datasets. These solutions minimize the risk of data loss and enhance the security of production lines. |

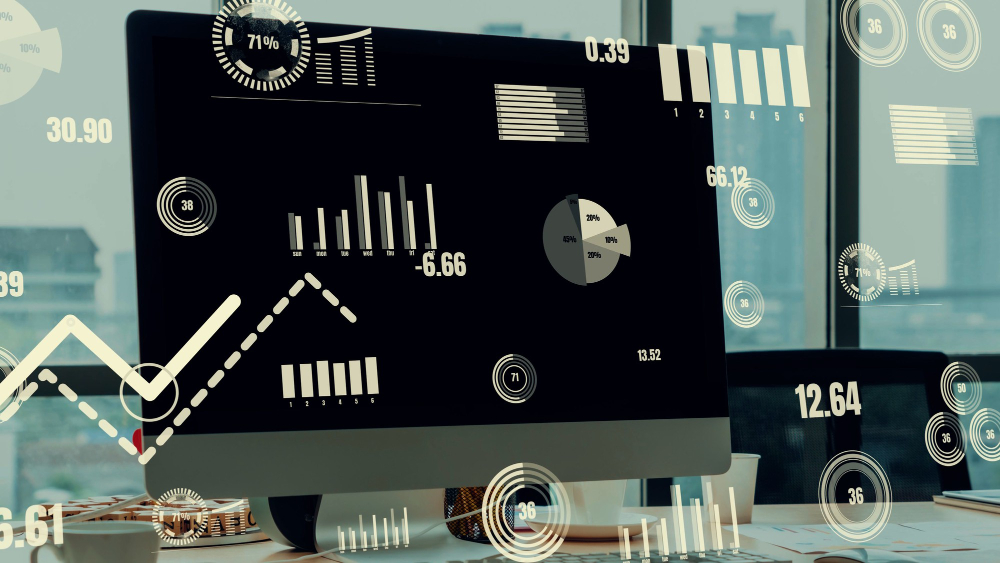

What Results Do We Achieve?

With our data-analytics-enhanced Industry 4.0 solutions, businesses achieve tangible success in their digital transformation journeys.

Analytical Scales:

- IoT Performance Index (IPE)

- AI-Powered Decision Index (ADCI)

- Cyber-Physical Performance Index (CPPI)

- Flexible Production Index (FPE)

- Data Security Performance Index (DSPI)

Real-Time Monitoring and Performance Reporting

Real-Time Monitoring Systems enable continuous oversight of production processes. These systems identify bottlenecks in advance and provide opportunities for immediate intervention.